Interactive Grid Hardware

Maverick Concepts

15 Weeks

Fall 2022

Solo Project

Maverick Concepts is a creative design and fabrication lab. They partner with clients to make impactful visual experiences.

A subset of Maverick Concepts, Artizin, which has yet to go public, produces a sound dampening PET felt they named “Artfelt”. I was tasked to create a B2B product utilizing Artfelt’s properties.

Understanding the Goal

Brainstorming:

Businesses, communities, and opportunities that might benefit from sound dampening felt, as well as areas for testing.

Class shared google doc of opportunities.

Learning:

Multiple magazines and books about designing for businesses, new-to-market products, etc., were studied.

Field research was conducted, visiting places in Auburn, Al that have or could use sound dampening products.

Key Findings:

Sound dampening is most heavily used in public work spaces like offices, libraries and coffee shops.

There are endless shapes and applications for sound dampening felt, can I make something with additional utility?

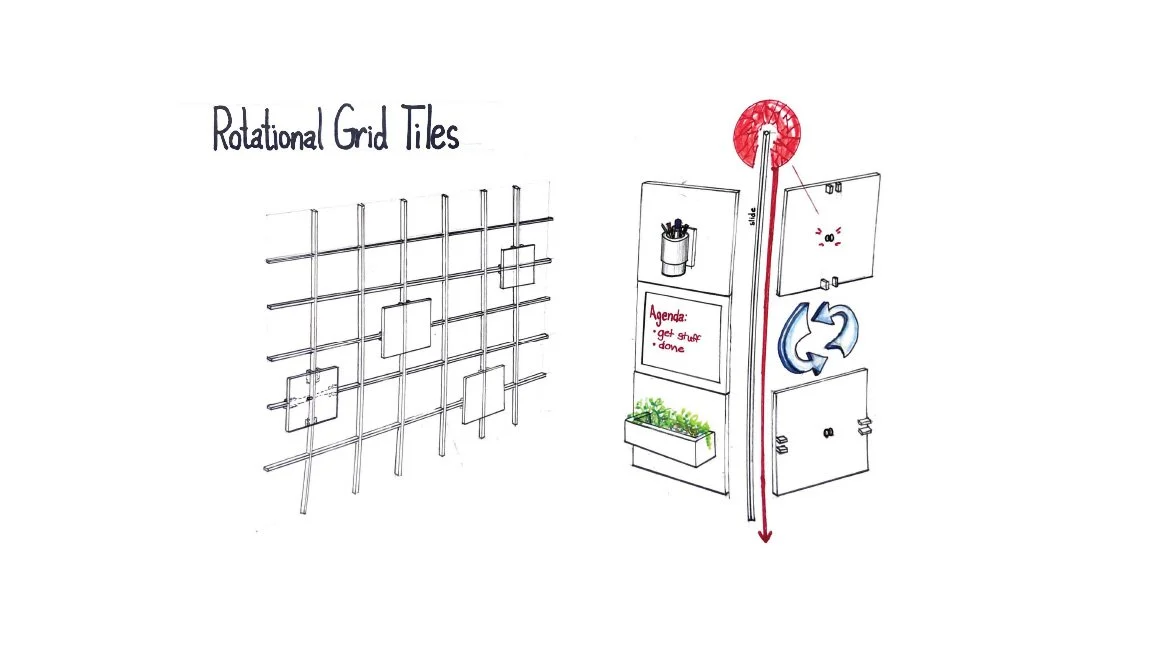

Concept Generation

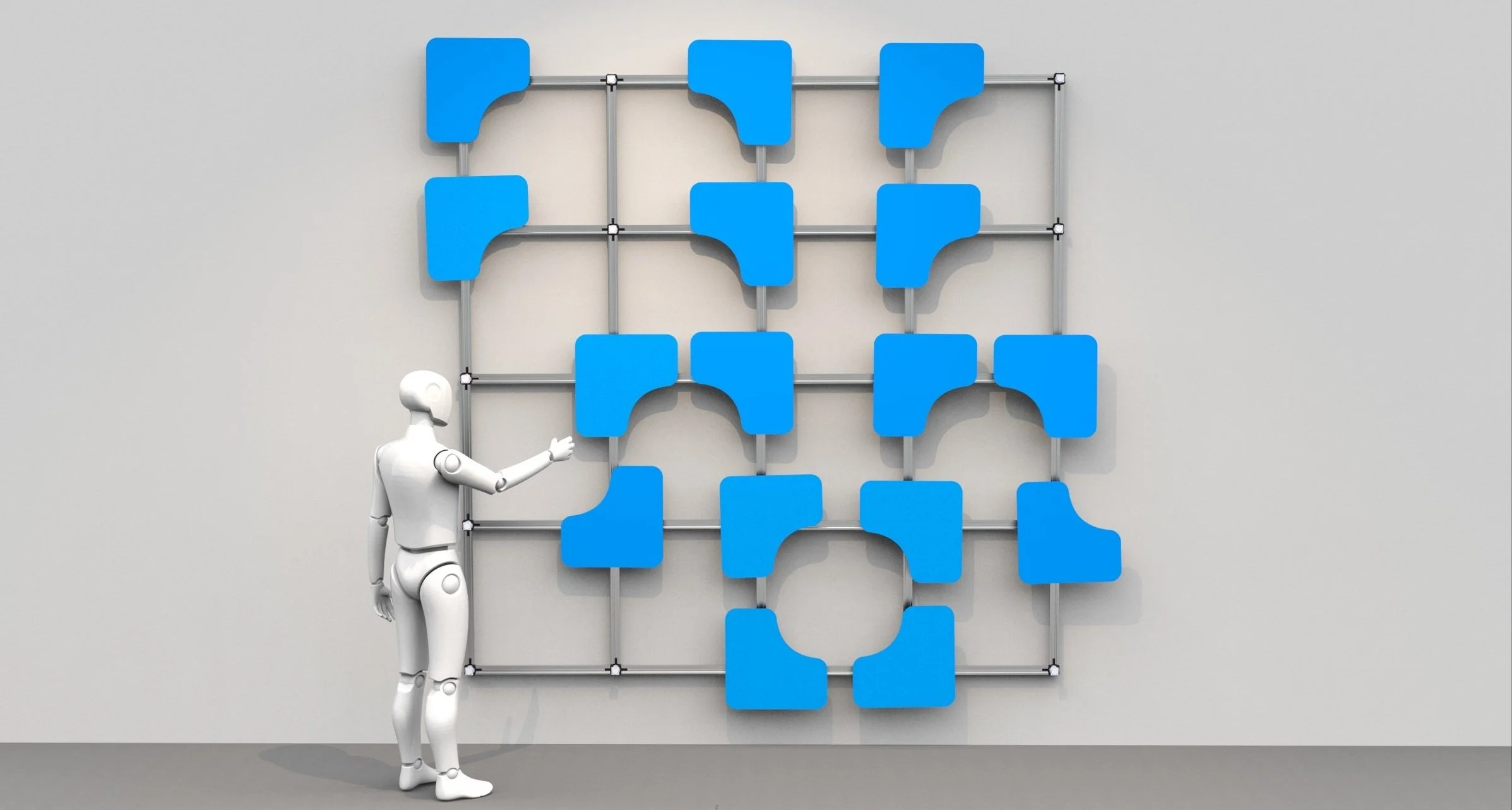

Chosen Concept

Classmates, teacher and Maverick sponsors voted for a favorite and most “practical” concept for each student to continue with.

What needed to be figured out:

- How the Artfelt tiles will attach, slide and rotate.

- Make tiles that benefit from being rotated.

- How to assemble the grid.

Solution

Hardware that holds Maverick’s pre-made aluminum extrusions together, while allowing for a slider that attaches to Artfelt, to slide through the extrusions and rotate at the node.

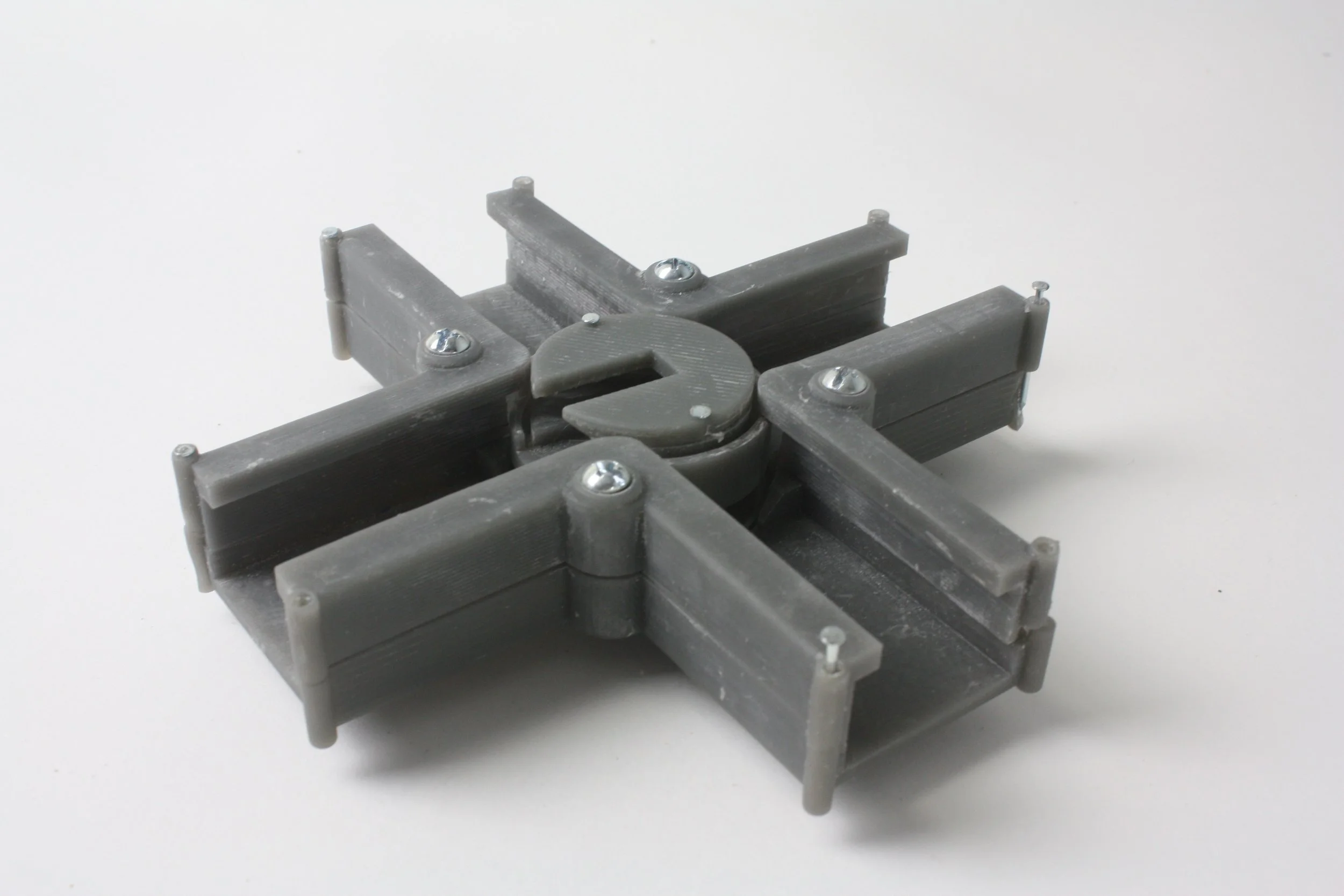

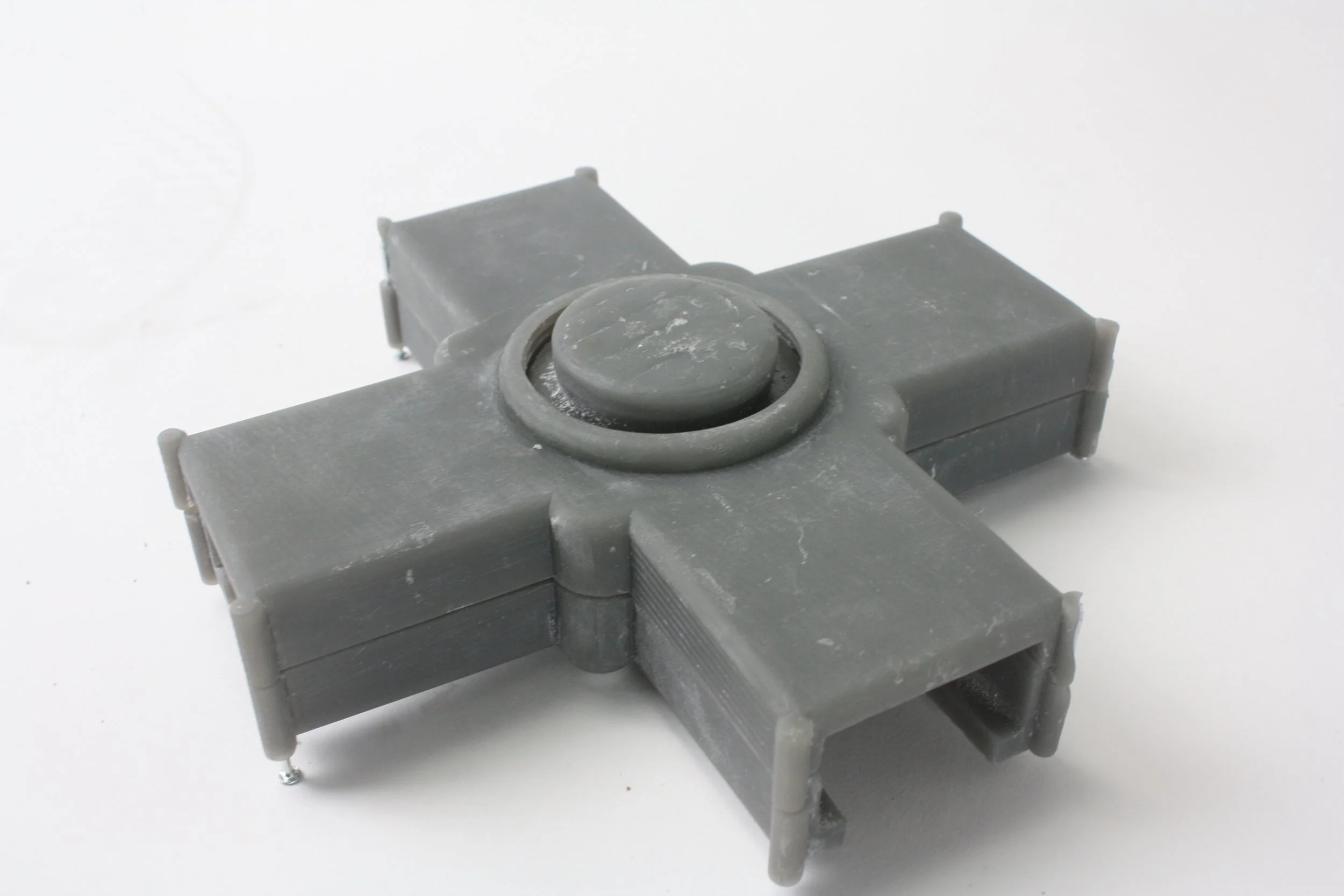

3D Printed Model #1

Many sliders were explored, this particular one was an articulating hinge slider that allowed for the Artfelt to rotate in three dimensions.

Node-tightening knob on back.

What worked:

- Hardware that holds aluminum extrusions.

- Node that hits resistance at 90 deg., allowing for slider to easily go through into the extrusions.

- Node-tightening knob.

What needed fixing:

- Slider needs to pop in at the node.

- Too big for Maverick’s injection molder.

- Too complex for assembly.

- Improve ergonomics of node-tightening knob.

- The key that attaches to Artfelt wouldn’t work because making an undercut on the Artfelt isn’t manufacturable.

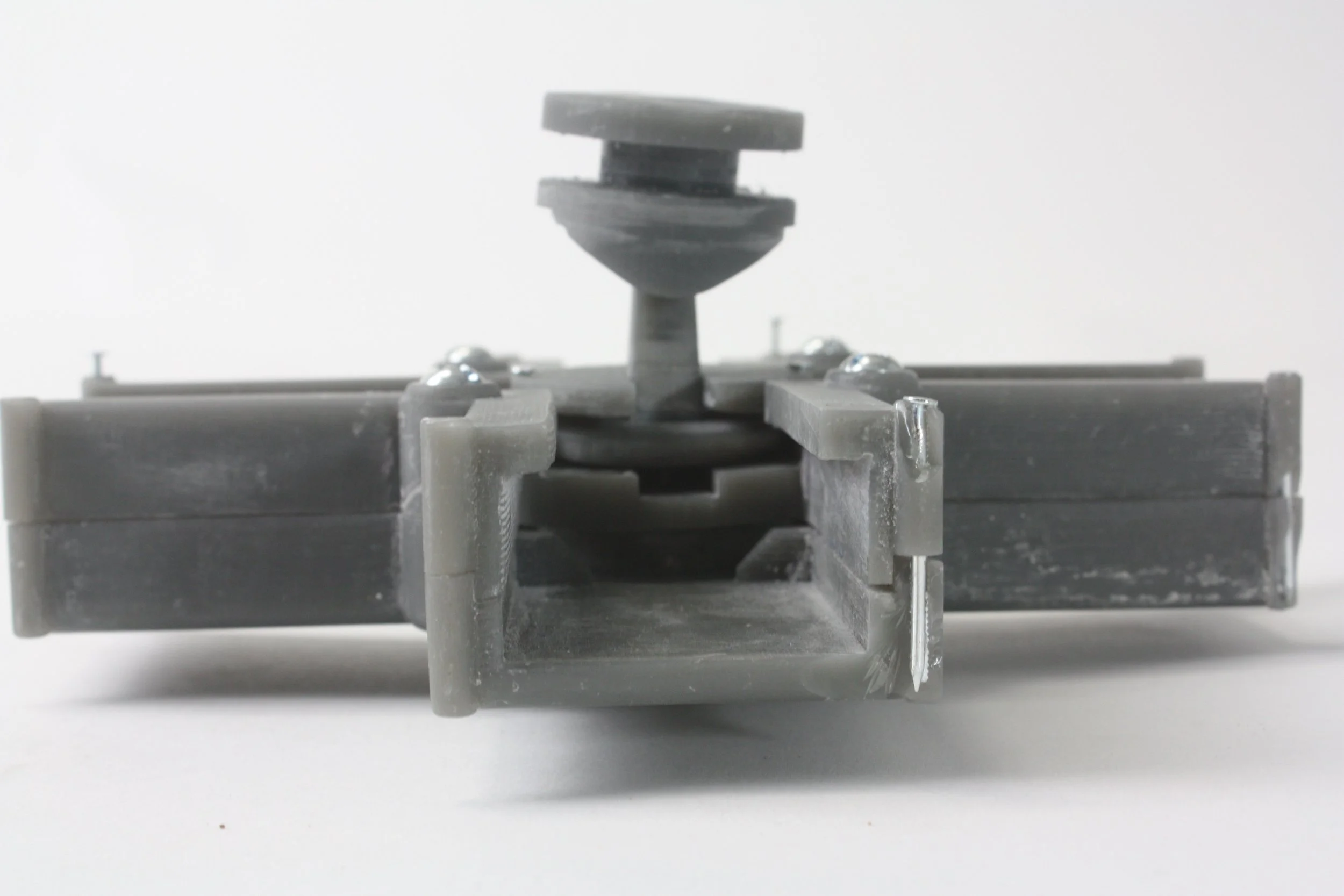

Update

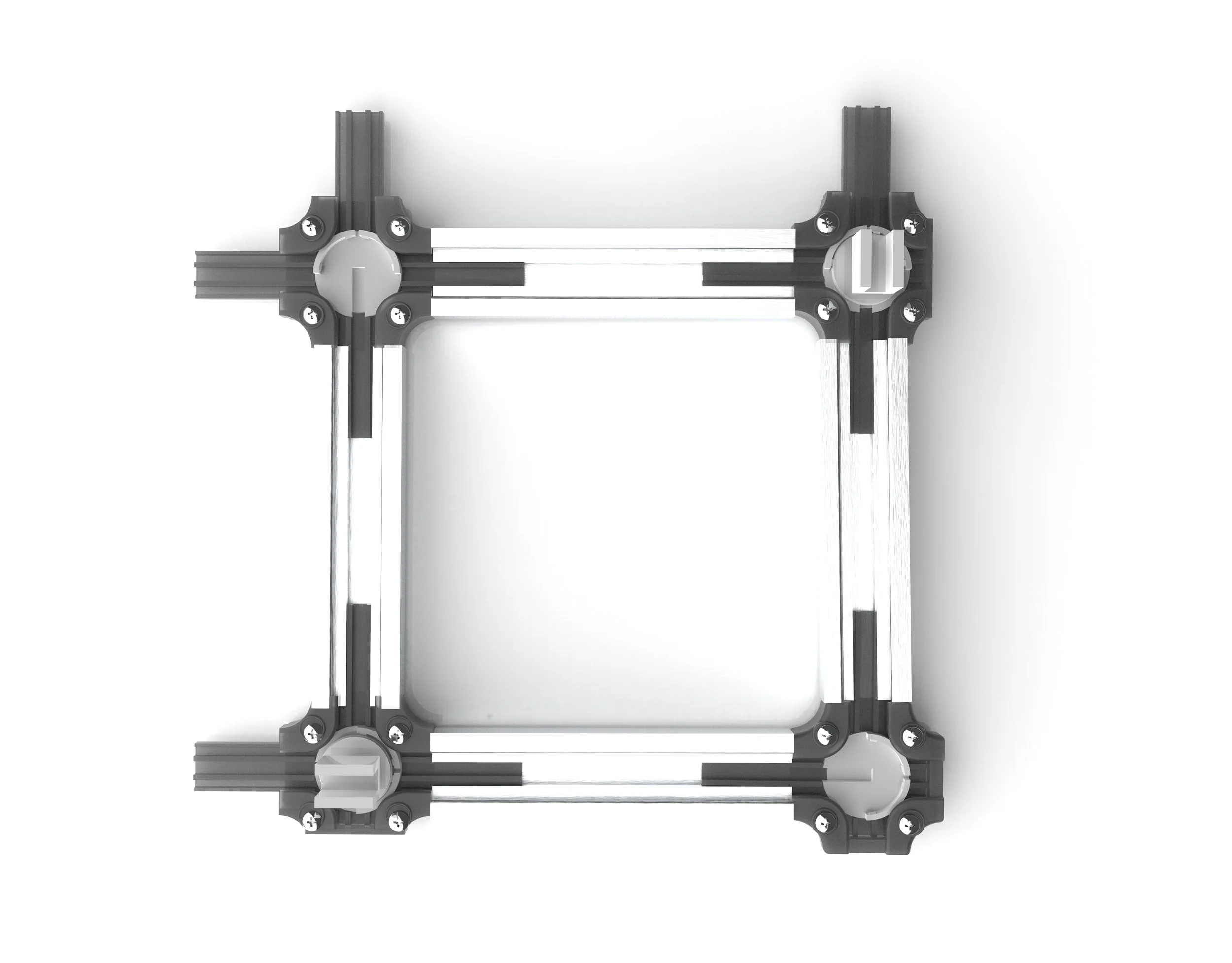

Hardware that’s seamless with the aluminum extrusions. The slider snaps into the semicircle node using snap fit. The slider is also equipped with a rectangular key that rotates the node.

Model #2

Draping/perpendicular Artfelt slider

What still needed fixing:

- Better snap fit node.

- Get rid of 4 top screws.

- Shorten rail stabilizers.

- Think about assembly and applications- feet or a wall mount?

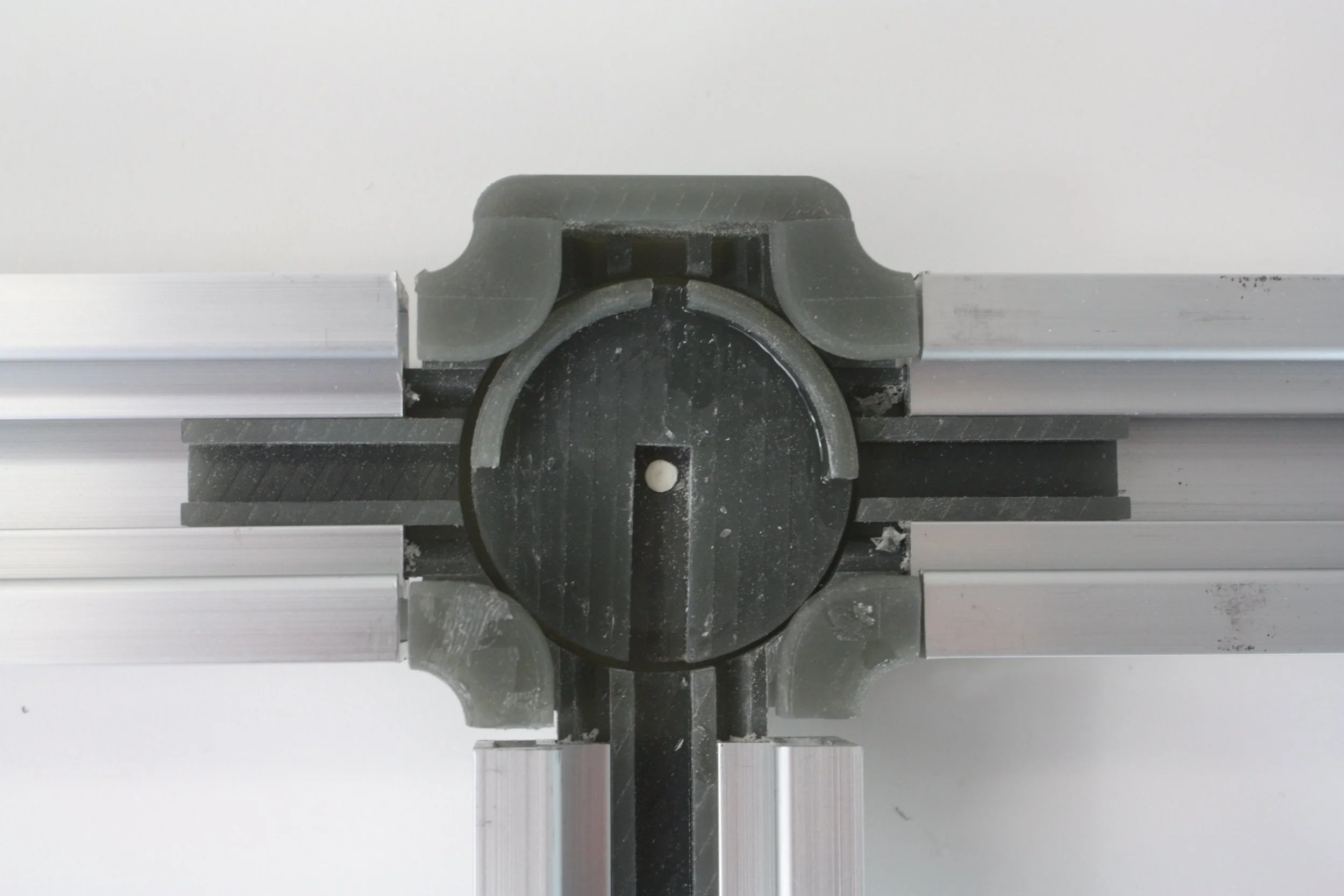

Final Model

Room divider can be taut between floor and ceiling.

Parts from top to bottom:

Magnetic attachment to Artfelt slider that snaps into node with a beveled edge, equipped with a rectangular key at the bottom.

Top parts are seamless with the aluminum rails, snap into bottom part, and help hold in the slider while it’s sliding.

Node has a lip that goes around in a semicircle as well as a slot for the rectangular key and a hole for the screw.

Partially threaded screw that screws into the node-tightening knob.

Improved ergonomics of node tightening knob.

Final 3D printed model

First Model to last model

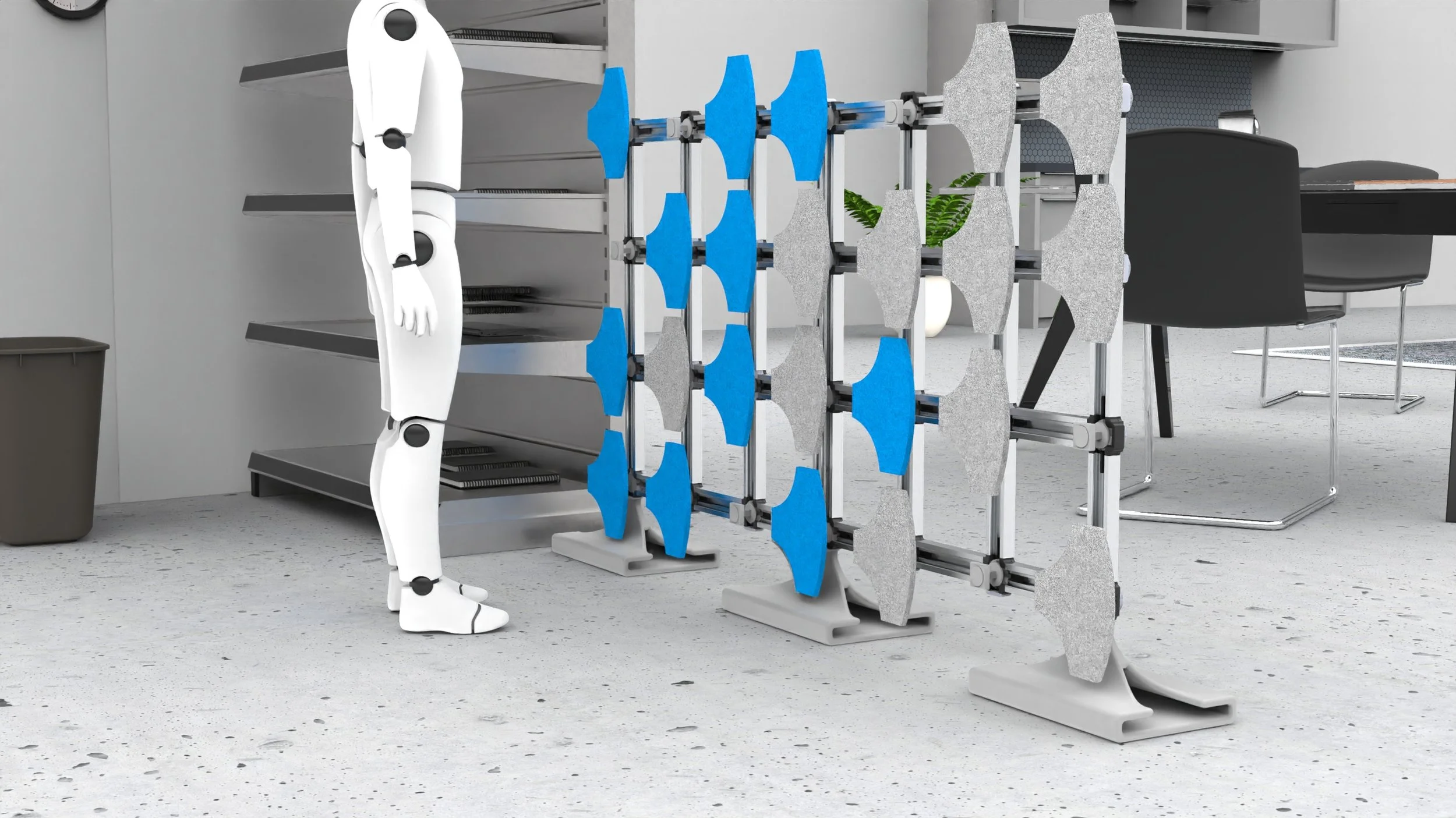

Not limited to panel shape or any specific rail length or configuration.

Extrusions extend beyond the system and enter any of the different feet that I designed.

Or mount it to the wall!

“I love this idea and your final project looks great! As soon as I saw your first model, I told Jim I had to have it because the endless possibilities that can be created with it, is really where the money is at.”

- Micah Gamache

Maverick Concepts Lead Product Designer